Kumenya ndi Kufa Pakupondereza Mapiritsi

Mawonekedwe

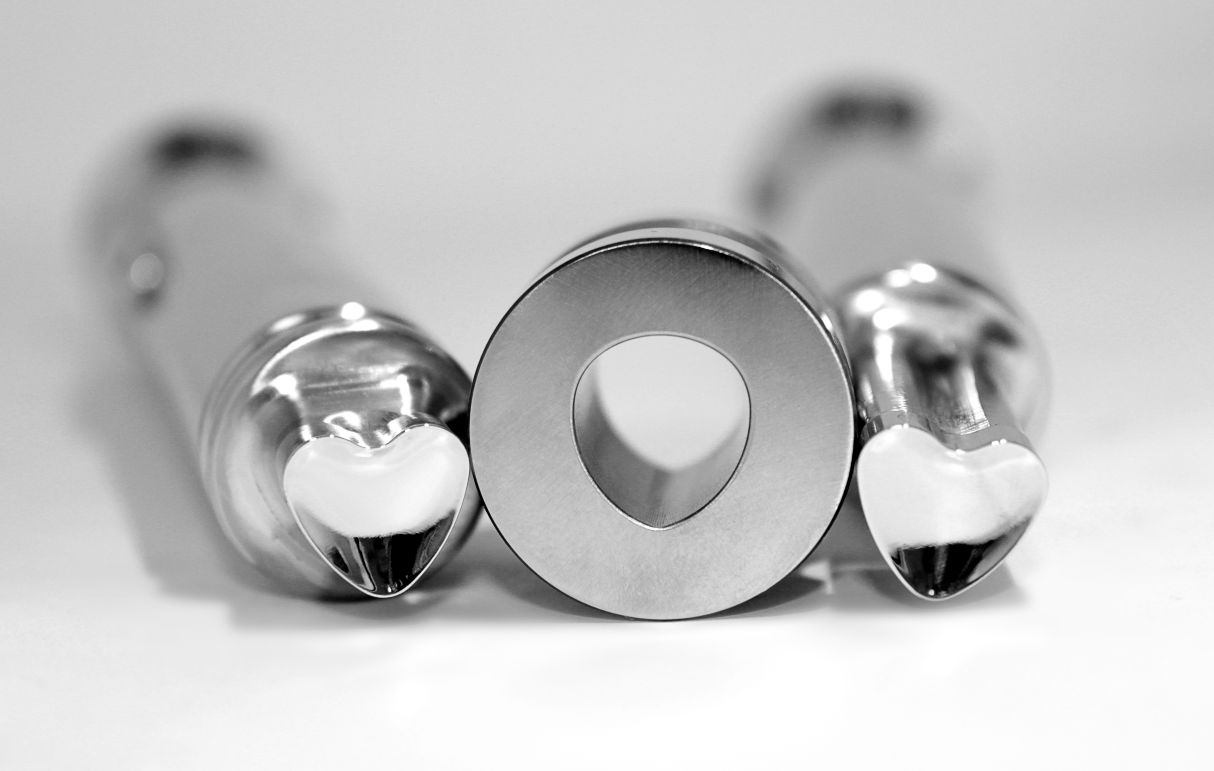

Monga gawo lofunika kwambiri la makina osindikizira a mapiritsi, zida zopangira mapiritsi zimapangidwa tokha ndipo khalidwe lake limayendetsedwa mosamala. Ku CNC CENTER, gulu la akatswiri opanga mapepala limapanga ndi kupanga mosamala zida zilizonse zopangira mapiritsi.

Tili ndi luso lochuluka popanga mitundu yonse ya zibowo ndi ma dies monga mawonekedwe ozungulira komanso apadera, concave yozama, concave yozama, bevel edges, de-tachable, single tip, multi tip komanso hard chrome plating.

Sitikungolandira maoda okha, komanso timapereka mayankho onse a kukonzekera bwino kuti tithandize makasitomala kupanga zisankho zoyenera.

Kudzera mu kusanthula kwatsatanetsatane kwa oda pasadakhale ndi gulu lodziwa bwino ntchito yothandiza makasitomala kuti apewe mavuto. Ndi kuwongolera kokhwima kwa njira zopangira komanso lipoti lomaliza lowunikira kuti zitsimikizire kuti Tooling iliyonse ikhoza kupirira mayeso.

Malinga ndi zofunikira za makasitomala, sitingopereka ma punch ndi ma dies okhazikika, monga EU ndi TSM, komanso chida chapadera chopangira ma tableti kuti tikwaniritse zosowa za makasitomala. Zipangizo zosiyanasiyana zopangira ma punch ndi ma dies komanso zokutira, zomwe zitha kukonzedwa bwino ndi zaka zambiri.

Zipangizo za tableting zapamwamba kwambiri zimathandiza makina osindikizira mapiritsi kupanga mitundu yosiyanasiyana ya mapiritsi. Zipangizo zosiyanasiyana zimapangitsa kuti ntchito yotulutsa ikhale yabwino kwambiri komanso kuchepetsa nthawi yopangira.

Kukonza

1. Pambuyo poti ntchitoyo yatha, kuwunika kwathunthu kwa Tooling ndikofunikira;

2. Tsukani ndi kupukuta nkhungu yonse kuti muwonetsetse kuti Tooling ndi yoyera;

3. Tsukani zinyalala mu Tooling kuti muwonetsetse kuti palibe mafuta otayira m'bokosi la zinyalala;

4. Ngati yasungidwa kwakanthawi, iponyereni ndi mafuta oletsa dzimbiri mutatsuka ndikuyiyika mu kabati ya Tooling;

5. Ngati Tooling idzagwiritsidwa ntchito kwa nthawi yayitali, yeretsani ndikuyiyika m'bokosi la nkhungu lomwe lili ndi dizilo pansi.

Magulu a zinthu

Kalata Yathu Ya Sabata Iliyonse

Ndi mfundo yodziwika bwino kuti wowombola adzakhutira ndi

tsamba lowerengeka lomwe lingathe kuwerengedwa mukayang'ana.

-

Imelo

-

Foni

-

WhatsApp

-

Pamwamba